Anode Rod Inspection Checker

Answer the following questions about your water heater's anode rod to determine if it needs replacement.

When your hot‑water supply starts tasting metallic or the water turns cloudy, the culprit is often a worn‑out anode rod. This small metal tube inside your water heater works like a sacrificial shield, rusting away to protect the tank. If it fails, corrosion can spread, shortening the heater’s life and causing costly leaks. Below is a step‑by‑step guide to help you decide if the rod needs swapping, what tools you’ll need, and how to avoid the most common mistakes.

Why the Anode Rod Matters

Anode rod is a sacrificial metal component installed in the tank of a water heater to prevent corrosion of the steel casing. It typically contains magnesium, aluminum, or a zinc‑aluminum alloy. As water circulates, the rod corrodes first, sparing the tank. When the rod is exhausted, the tank itself becomes the next target, leading to rust, leaks, and reduced efficiency.

Common Signs Your Anode Rod Is Failing

- Water smells like rotten eggs or metallic-especially after a shower.

- Yellow or brown water appears when you first turn on the hot tap.

- Visible rust or white‑powdery deposits inside the tank (you’ll need to drain the heater to see this).

- Unexplained drops in water temperature despite a working thermostat.

- Increased electricity or gas usage because the heater works harder.

While any one of these clues might be unrelated, three or more together usually point to a rod that’s near the end of its life.

Tools and Materials You’ll Need

- Adjustable wrench or socket set (usually ½-¾ inch).

- Screwdriver (to remove the access panel).

- Garden hose (for draining water).

- Bucket or large container (to catch drips).

- Protective gloves and safety glasses.

- Flashlight or headlamp for better visibility.

If you plan to replace the rod, also have the appropriate replacement rod (magnesium, aluminum, or hybrid) that matches your heater’s size and voltage ready.

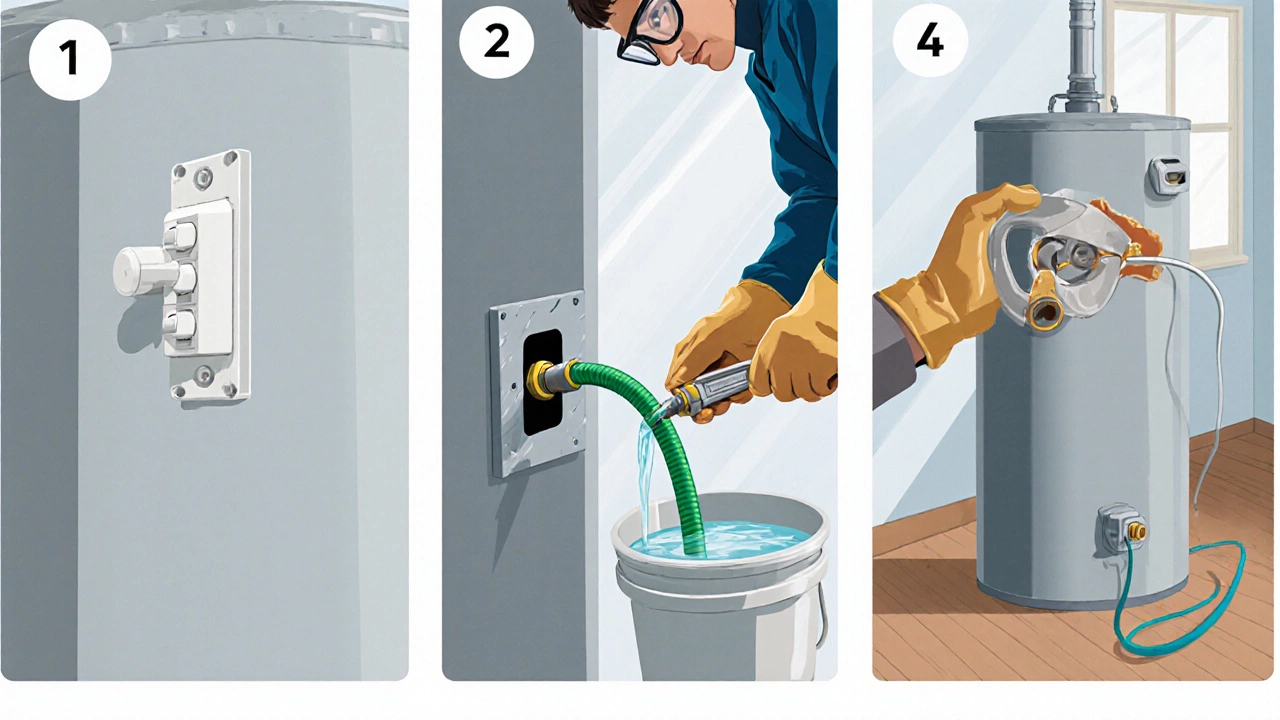

Safety First: Shut Off Power or Gas

Before you get under the tank, turn off the energy source:

- For electric heaters, switch off the breaker at the main panel.

- For gas heaters, turn the gas valve to the “off” position and wait a few minutes for any residual gas to clear.

- Close the cold‑water supply valve located on the top or side of the heater.

- Open a hot‑water faucet in the house to relieve pressure.

These steps dramatically lower the risk of electric shock or gas exposure while you work.

How to Inspect the Anode Rod

1. Locate the access panel. Most heaters have a small removable panel on the side. Use a screwdriver to pop it open.

2. Find the rod. It looks like a thick, threaded metal bolt sticking out of the tank. The head often has a hex slot.

3. Measure the length. Using a ruler, note how much of the rod protrudes. If you can see less than half of its original exposed length, corrosion is likely severe.

4. Pull the rod gently. With an adjustable wrench, loosen the hex nut counter‑clockwise. If it resists, apply steady pressure; forcing it can damage the tank threads. When it comes out, inspect the metal:

- Bright, metallic appearance - the rod is still good.

- Heavy rust, pitting, or a crumbling surface - replace it.

- If the rod feels unusually light, it may be hollow from corrosion inside.

5. Check the water inside the tank. If you’re comfortable, briefly drain a few gallons into a bucket. Clear water means the rod is still protecting the tank; murky, rusty water signals internal corrosion.

Interpreting What You Find

| Attribute | Good Rod | Bad Rod |

|---|---|---|

| Surface condition | Shiny, intact metal | Rusty, pitted, flaking |

| Length exposed | More than 50% visible | Less than 25% visible |

| Weight | Matches manufacturer specs | Noticeably lighter (material loss) |

| Water appearance after drain | Clear, no sediment | Brownish or cloudy |

If the majority of columns line up with the “Bad Rod” side, schedule a replacement right away.

When to Replace the Anode Rod

The general rule of thumb is to inspect the rod every 12‑24 months and replace it every 3‑5 years, depending on water hardness and rod material. Magnesium rods corrode faster in hard water, while aluminum rods last longer but may produce a metallic taste. Hybrid rods (mag‑al) offer a middle ground.

Replace the rod if you see any of the following:

- More than 50% of the rod has corroded away.

- Rust particles are visible in the tank water.

- The heater is less than three years old but the rod is already near the end of its lifespan (common in very hard‑water areas).

It’s cheaper to act now than to endure a tank leak that could flood your basement.

Step‑by‑Step Replacement Guide

- Drain the heater completely by attaching a garden hose to the drain valve and opening a hot‑water faucet.

- Unscrew the old rod using the wrench and remove it.

- Inspect the tank threads for damage; clean with a wire brush if needed.

- Wrap Teflon tape around the threads of the new replacement anode rod to ensure a seal.

- Insert the new rod and tighten the hex nut securely (don’t overtighten).

- Close the drain valve, open the cold‑water supply, and let the tank fill.

- Restore power or gas, then test the hot water to confirm normal operation.

Most homeowners can finish this job in under an hour with basic tools.

Preventive Tips to Extend Rod Life

- Install a water‑softener if you live in a hard‑water region.

- Run the heater at a moderate temperature (120°F/49°C); higher temps accelerate corrosion.

- Schedule annual inspections, especially after winter when water chemistry can shift.

- Consider a dual‑rod system for larger tanks; it offers redundancy.

These habits keep the inner tank stainless and the rod from going flat too quickly.

Frequently Asked Questions

How often should I check my anode rod?

Inspect it at least once a year. In hard‑water areas, a 6‑month check is wiser.

Can I replace a faulty rod myself?

Yes, most homeowners can replace it with basic tools. Just follow safety steps and ensure the tank is fully drained.

What’s the difference between magnesium and aluminum rods?

Magnesium corrodes faster, offering stronger protection in soft water but wears out quickly. Aluminum lasts longer in hard water but may cause a metallic taste.

Will a bad anode rod cause my heater to stop heating?

Not immediately. The heater will keep working until the tank starts corroding, which eventually leads to reduced efficiency and possible leaks.

Is there a way to tell if the water heater tank itself is corroded?

If you see rust flakes, brown water, or a rusty smell during a drain, the tank is likely corroded. At that point, replacement is often more cost‑effective than repair.